We haven’t even completely developed the technology yet or explored its full potential but we’re still more than well aware of the numerous benefits of 3D printing. In fact, if you read our last post on advantages of 3D printing, you probably know more about the boon than is 3D printing than most people.

We haven’t even completely developed the technology yet or explored its full potential but we’re still more than well aware of the numerous benefits of 3D printing. In fact, if you read our last post on advantages of 3D printing, you probably know more about the boon than is 3D printing than most people.

In fact, we know of these advantages even though the 3D printing technology is still not affordable enough for the masses. However, like all great technologies (remember, dynamite was originally invented for construction and mining purposes), there are not only advantages of 3D printing but also disadvantages of 3D printing.

So, the objective of this post is to reveal to you, dear reader, not only the various advantages of 3D printing but also its disadvantages. Before we do that though, we need to understand a little more about the nature of these disadvantages of 3D printing.

The Disadvantages of 3D Printing

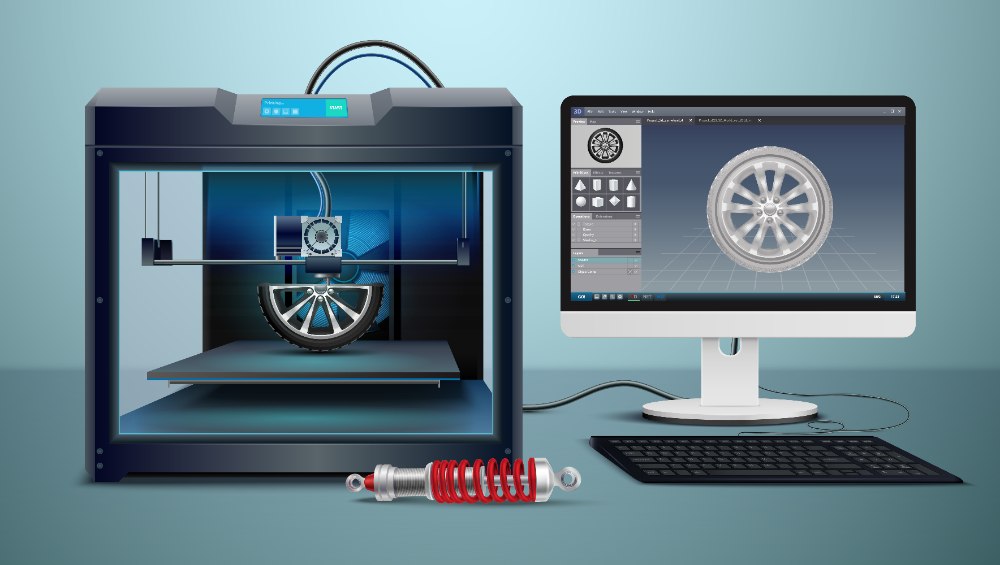

3D printing is most relevant in the world of manufacturing. While we, as individual consumers, may enjoy the absolute freedom of creation that 3D printers give us, at the end of the day we’ll only be tinkering with the technology.

3D printing is most relevant in the world of manufacturing. While we, as individual consumers, may enjoy the absolute freedom of creation that 3D printers give us, at the end of the day we’ll only be tinkering with the technology.

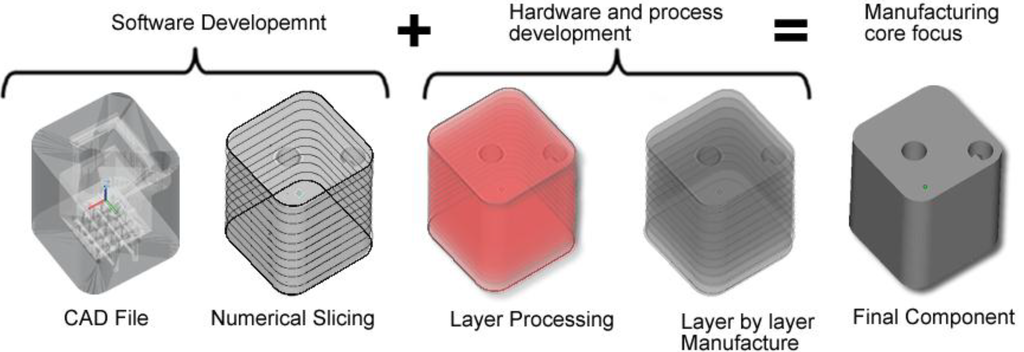

In other words, 3D printing’s maximum impact will be felt through the manufacturing sector as opposed to the consumer sector. The reason for this is twofold. The first is that the applications of 3D printing are effectively limitless. There is nothing made by humanity that will not benefit from further development of 3D printing technology.

The other part of the reason is that 3D printing actually makes manufacturing processes easier, simpler, and more cost effective. These basic advantages of 3D printing are not that unlike automation. When machines started getting automated due to the Digital Revolution of the last couple of decades, similar advantages were noticed.

At the same time, there were people citing disadvantages of automation as well. The same holds true for 3D printing. Most of the disadvantages of 3D printing are similar to the disadvantages of automation. However, as in the case of automation, further development of the technology will result in these disadvantages of 3D printing becoming null and void.

We still have to know what these disadvantages are, though, to understand 3D printing better. So, here’s a list for your benefit.

Scale and Size Are Limitations of 3D Printing

In 3D printing, objects are produced one at a time. As per the current state of 3D printing technology, this is one of those things that cannot be questioned. You cannot print multiple objects of the same type at the same time.

The fact that multiple items cannot be simultaneously produced on a 3D printer isn’t its only limitation with respect to scale and size. Another limitation is the size of the object being printed.

The majority of 3D printers of today can only print items measuring up to 1 cubic yard if polymer is used and only 1 cubic foot if metal is used. While 3D printers have been used to print whole houses, the houses being built had their own limitations. Moreover, the 3D printer used in the printing of those houses isn’t commercially available yet.

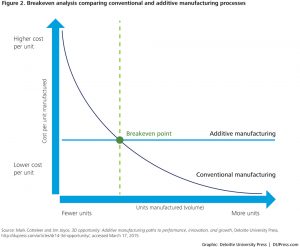

3D Printing Belies Economies of Scale

The fact that products or objects are produced one at a time in 3D printing gives us the benefit of maximum customisation potential. However, this same fact also gives us one of the more potent disadvantages of 3D printing i.e. the absence of economies of scale in 3D printing.

The fact that products or objects are produced one at a time in 3D printing gives us the benefit of maximum customisation potential. However, this same fact also gives us one of the more potent disadvantages of 3D printing i.e. the absence of economies of scale in 3D printing.

Economies of scale can be defined as cost advantages gained by manufacturers when they ramp up the scale and size of their manufacturing systems. Simply speaking, when mass production improves the profit margins of manufacturers the phenomenon can be called economies of scale.

As of now, the phenomenon of economies of scale isn’t really possible in 3D printing because every object or product is printed individually. However, this flaw is offset by low cost of production and virtually zero waste generation in 3D printing.

Cost of Buying and Setting up A 3D Printer Is Very High

The biggest of the disadvantages of 3D printing is the cost factor. While it is true that over its whole life a 3D printer ends up paying for itself more than once, the initial cost still remains something of a roadblock for most businesses and individuals.

The biggest of the disadvantages of 3D printing is the cost factor. While it is true that over its whole life a 3D printer ends up paying for itself more than once, the initial cost still remains something of a roadblock for most businesses and individuals.

For instance, top end 3D printing devices or additive manufacturing machines can end up costing anything between $300,000 and $2 million. Furthermore, even the consumables can end up costing a pretty penny with prices ranging from $100 to $200 for every pound consumed.

Finally, even though skilled labour is not a requirement for running 3D printers, the technology is still new enough for there to not be enough people able to operate them. Also, it is worth mentioning that truly revolutionary use of 3D printing can require whole teams of CAD trained professional, which can also cost a good amount of money to set up.

3D Printed Objects May Require Heavy Duty Post Processing

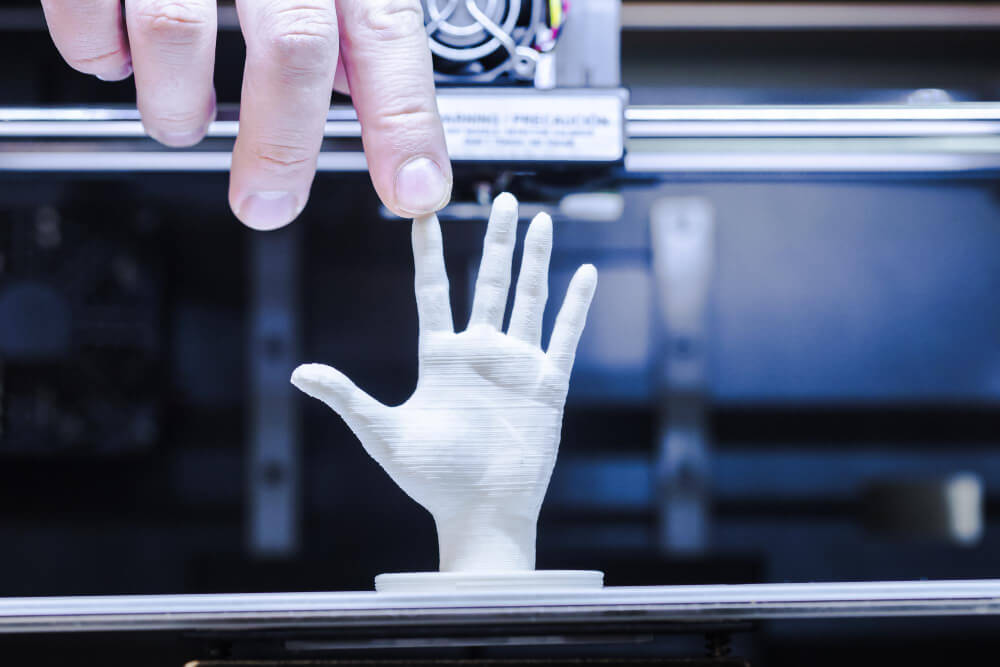

When it comes to the disadvantages of 3D printing, one that anyone who has seen 3D printing live can spot is the poor finishing quality of the object printed. The quality of the finish can leave a lot to be desired in a 3D printed object. Moreover, it isn’t only the lack of polish that is the problem but also the possible dimensional inaccuracy.

When it comes to the disadvantages of 3D printing, one that anyone who has seen 3D printing live can spot is the poor finishing quality of the object printed. The quality of the finish can leave a lot to be desired in a 3D printed object. Moreover, it isn’t only the lack of polish that is the problem but also the possible dimensional inaccuracy.

Both these problems, however, can be resolved with post processing methods. Even though the post processing methods in question aren’t incredibly complex or tedious, the fact that they are required can be added to the list of disadvantages of 3D printing.

Large Scale Adoption of 3D Printing Will Result In Significant Job Loss

Every invention is designed to solve a problem or make a particular task easier. Since that problem or that task was earlier performed by an individual, it can be said that every new invention ends up taking away jobs amongst the masses.

This is something that has been seen throughout history. It happened during the Industrial Revolution, it happened during the Digital Revolution, and it happened when industries tried to automate. More importantly, it is going to happen incessantly in the future as well.

The development of self-driving cars will result in chauffeurs getting redundant, the invention of automatic diagnosing machines will cause diagnosticians to become highly specialised, and the availability of 3D printers will cause many machine operators to lose their jobs.

The potential loss of jobs is another element that can be added to the disadvantages of 3D printing. Nonetheless, this disadvantage is something of a non – starter because new technologies almost always end up generating newer jobs. People just have to adapt and acquire new skills to be qualified for those new jobs.

For example, if postmen became scarce because of emailing, IT managers grew in numbers. If the number of farmers declined due to the invention of the steam engine, the number of machine operators grew in force. Similarly, if 3D printing is going to result in lesser machine operators, the number of CAD professionals will grow.

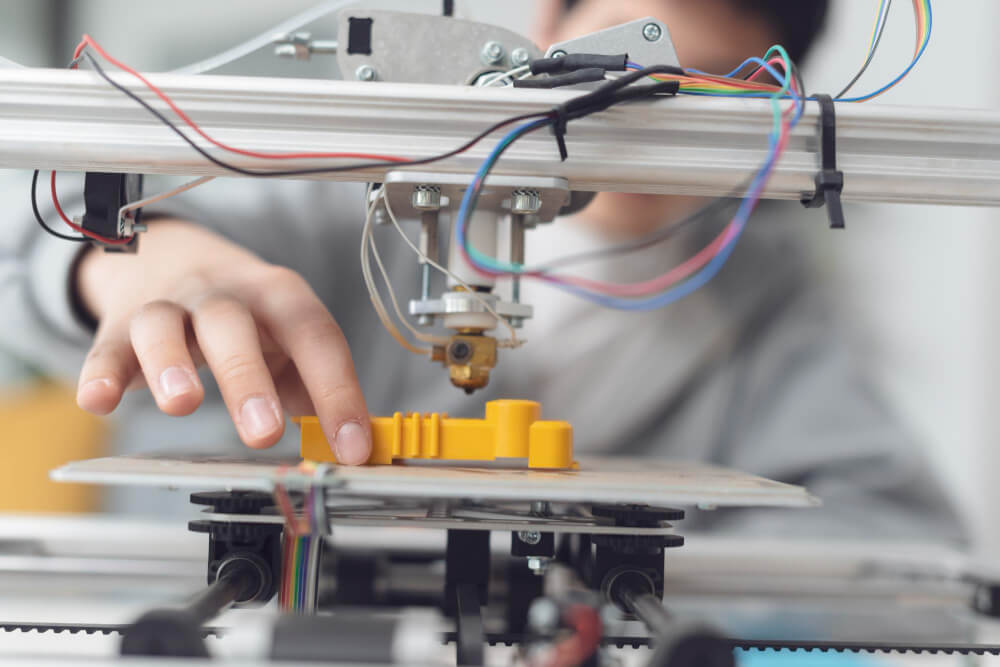

3D Printers Aren’t Easy To Use

When it comes to 3D printers, people often think they are easy to use and very helpful. However, the truth is that they can be quite tricky to operate and manage. You need special equipment, high-voltage power supplies, and specific parts, which can make it tough for regular users. Additionally, some 3D printers have limitations like low resolution and the inability to connect to Wi-Fi. But don’t worry! Progress is being made, and 3D printing is gradually becoming more accessible and user-friendly.

The Overuse Of Plastics

Popular and affordable 3D printers currently use plastic filaments, which generate waste and contribute to landfill pollution. PLA filament is biodegradable, but the most common type, ABS, is not. This limits the variety of products that can be made. In order to be more beneficial for manufacturers and consumers, future 3D printers should utilize alternative materials like metal and carbon composites, similar to some current models.

Dangerous Weapons Production

The use of 3D printers has raised concerns because they can be used to create dangerous items such as knives, guns, and explosives. This means that criminals and terrorists have the potential to make these weapons without being easily detected. In fact, some criminal organizations have already utilized 3D printing to create card readers for bank machines, which can be used for illegal activities. As technology continues to improve, 3D printers are becoming more affordable and easier to use. This has led to worries that the production of unlicensed weapons may increase in the future, posing a threat to public safety.

Nice information you have given here but despite of disadvantages there are alot of advantages of 3d printing you have to mentioned that as well.