There’s a lot of noise about consumables i.e. ink and toner cartridges when it comes to 2D printing. This fuss about cartridges can be directly attributed to the 2D printing industry and the Original Equipment Manufacturers (OEM) therein. Therefore, one of the first things people interested in 3D printing wonder is whether the same situation is going to apply to 3D printing or not.

There’s a lot of noise about consumables i.e. ink and toner cartridges when it comes to 2D printing. This fuss about cartridges can be directly attributed to the 2D printing industry and the Original Equipment Manufacturers (OEM) therein. Therefore, one of the first things people interested in 3D printing wonder is whether the same situation is going to apply to 3D printing or not.

The answer is that it won’t. In 2D printing, cartridges are expensive because the OEMs have chosen the razor business model where the cost of the main device (printer or razor) is subsidised while the cost of consumables is used to offset the subsidisation. In fact, the 3D printing filaments aspect of additive manufacturing is going to be quite different from the nature of the 2D printing consumables industry. Consider.

Why Are 3D Printing Filaments Important?

3D printing filaments are actually quite important in the big scheme of things with respect to the development of 3D printing technology as a whole. In fact, one of the directions in which the 3D printing technology is going to develop in the near future is that of filaments. Although, most experts will focus on the cost effectiveness and user friendliness of 3D printing technology, development of 3D printing filament technology will also contribute to the overall evolution of the technology.

3D printing filaments are actually quite important in the big scheme of things with respect to the development of 3D printing technology as a whole. In fact, one of the directions in which the 3D printing technology is going to develop in the near future is that of filaments. Although, most experts will focus on the cost effectiveness and user friendliness of 3D printing technology, development of 3D printing filament technology will also contribute to the overall evolution of the technology.

The reason for this is that as the device develops in terms of cost effectiveness, ease of use, and speed of printing, the filaments will also have to keep up with that development. For instance, you can already see that developmental increments in the speed and efficiency of 3D printers have slowed down. These developmental increments will pick up again in the near future once the technology behind filaments begins to catch up with the current capabilities of 3D printing machines.

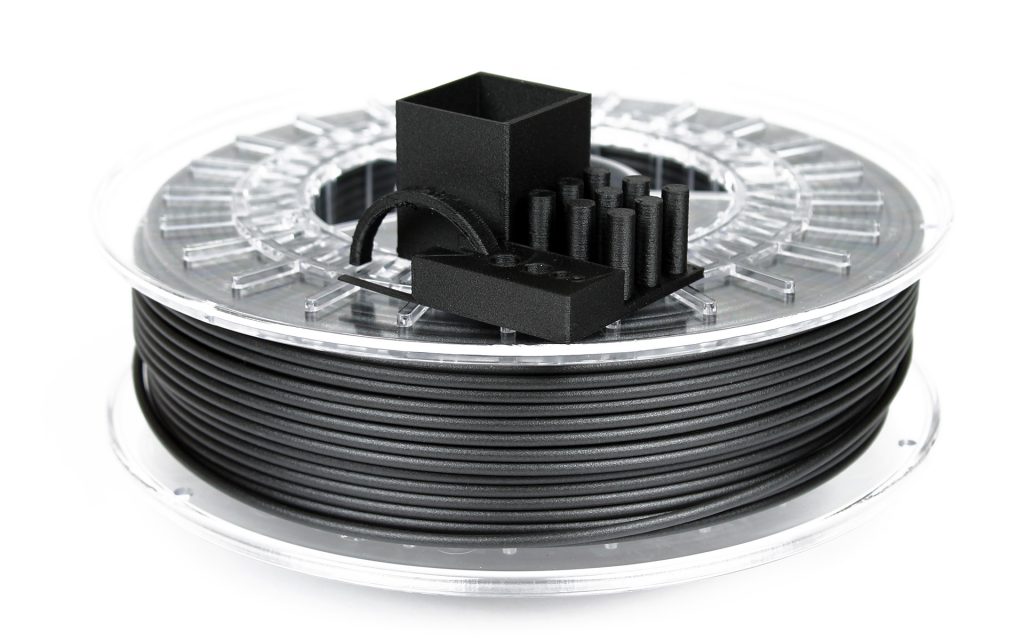

Even now, we can see a marked difference with the speed that new types of 3D printing filaments are becoming available. While the industry began largely with Acrylonitrile Butadiene Styrene (ABS) and Polyactic Acid (PLA), there are now many more options available to the 3D printing enthusiast. What are these options? Here’s a list just for you.

Where it all began…ABS & PLA

ABS is probably the most easily available of the different types of 3D printing filament that you can possibly get. ABS is so suitable for 3D printing because it has just the right type of strength and flexibility while having high glass transition temperature i.e. the temperature at which it starts losing its shape.

ABS is probably the most easily available of the different types of 3D printing filament that you can possibly get. ABS is so suitable for 3D printing because it has just the right type of strength and flexibility while having high glass transition temperature i.e. the temperature at which it starts losing its shape.

The reason why these characteristics are good in 3D printing is that they are facilitative when it comes to functional parts. In order to use, you should be prepared to spend time in post processing and also be ready to work with either heated beds or heated chambers. Raw 3D prints with ABS may look rough and unattractive but glossy and matte finishes can be achieved, if you’re willing to go the extra mile.

Heated beds and heated chambers are essential in the case of ABS filaments because when this plastic cools, it contracts. The variable shrinkage is a major problem with ABS 3D printing filaments and is known as warping in 3D printing lingo.

The heated bed slows down the cooling process which then prevents warping. It is also important to note that if you work with ABS, you will have to consider your environmental impact with respect to energy consumption (heated beds and chambers consume a lot of energy) as well as fumes (melting ABS releases unhealthy fumes).

A far more environment friendly option than ABS is PLA. PLA is a greener thermoplastic than ABS because it is produced from sugarcane or corn starch. Generally speaking, PLA filaments are far better for the common 3D printing enthusiast than ABS 3D printing filaments and their environment friendliness isn’t the only reason either. PLA melts at a much lower temperature than ABS and doesn’t even emit the bad smell that the latter is famous for.

PLA also flows better which makes it better than ABS when it comes to printing objects with more detailing to them. Furthermore, warping is not as big a deal with PLA as it is with ABS. For instance, it only becomes relevant with objects having a large flat bottom and can be countered with a heated bed at 60 degrees Celsius. Finally, PLA filaments, in the majority of cases, tend to produce glossier prints than ABS filaments.

3D Printing Filaments with Special Effects

One of the first variations in filaments that 3D printing enthusiasts got a chance to play with was colours. However, soon enough that morphed into 3D printing filaments with special effects. Special effects filaments are more common with PLA than ABS.

One of the first variations in filaments that 3D printing enthusiasts got a chance to play with was colours. However, soon enough that morphed into 3D printing filaments with special effects. Special effects filaments are more common with PLA than ABS.

The most available special effects ABS 3D printing filament would be one that changes colour on the basis of the temperature around it. In the PLA category of special effects filaments, you get quite a few options with the most notable ones being ‘glow in the dark’, ‘photochromatic’, and ‘sparkly’ filaments.

The Countless Blends of PLA 3D Printing Filaments

Here’s another reason why most home 3D printers opt to go with PLA 3D printing filaments. There are far more options to play with PLA filaments than there are with ABS filaments. For instance, you can get blends of PLA filaments where the filaments are blended with other substances to create different types of effects.

Here’s another reason why most home 3D printers opt to go with PLA 3D printing filaments. There are far more options to play with PLA filaments than there are with ABS filaments. For instance, you can get blends of PLA filaments where the filaments are blended with other substances to create different types of effects.

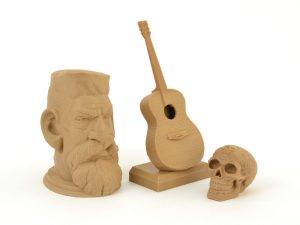

You can get wood based blends of PLA 3D printing filaments including pine wood, cherry wood, coconut wood, and even bamboo amongst others. Similarly, you can get metal based blends with options ranging from bronze and copper to brass, stainless steel, and even iron. In fact, there is no dearth of options when it comes to blends. Another blend worth considering is the brick blend.

Industry Strength 3D Printing Filaments

While prints made with PLA filaments are more brittle than prints made with ABS filaments, even ABS filaments won’t give you good strength metrics. However, if you’re looking for strong prints that can handle a lot of weight or display impact resistance, then there are other types of 3D printing filaments designed to provide industry level strength.

While prints made with PLA filaments are more brittle than prints made with ABS filaments, even ABS filaments won’t give you good strength metrics. However, if you’re looking for strong prints that can handle a lot of weight or display impact resistance, then there are other types of 3D printing filaments designed to provide industry level strength.

First of all, let’s get the PLA + PHA blend out of the way. You know that PLA is Polyactic Acid. PHA is Polyhydroxyalkanoate which is mixed with PLA in this blend to deal with the inherent brittleness of PLA. There are even stronger 3D printing filaments, if you find even this too weak.

Some of the strongest such filaments are PET or Polyethylene Terephthalate and its derivatives such as PETT and PETG, both of which are polymers of PET. Other types of filaments which exhibit industry class strength include nylon, XT Copolyester, and XT Carbon.

Flexible 3D Printing Filaments

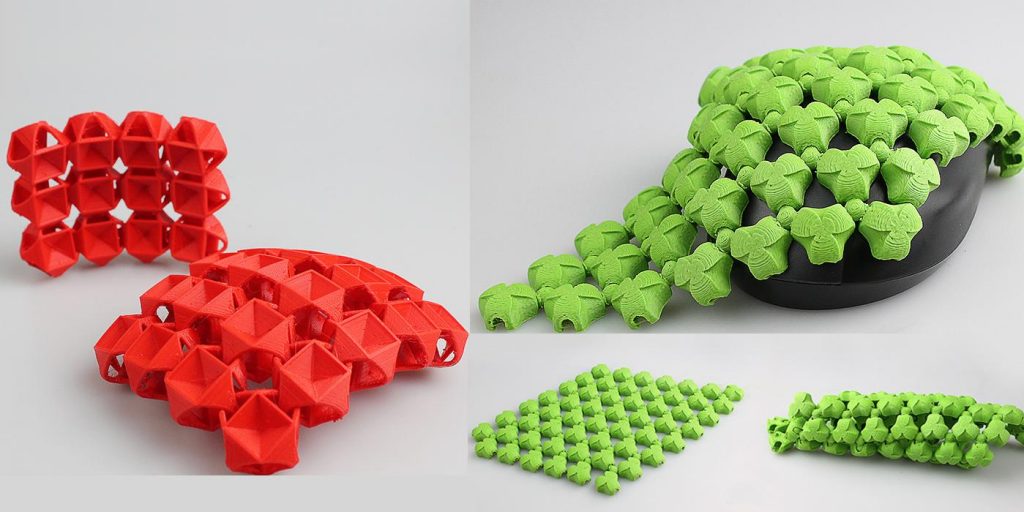

3D printing filaments aren’t always rigid and stiff. It is possible to get flexible or bendy filaments as well. Such filaments are available in both ABS and PLA categories.

3D printing filaments aren’t always rigid and stiff. It is possible to get flexible or bendy filaments as well. Such filaments are available in both ABS and PLA categories.

Smart or Bendable ABS 3D printing filaments are not only more bendy than your standard ABS filaments but also more sturdy and durable since they resist warping and shrinkage.

PLA filaments offer far more variety when it comes to flexibility and bendability. However, 3D printing with bendy filaments is not something that everyone can do because only specific types of 3D printers can print successfully with flexible filaments. For instance, your 3D printer will need to have Direct Drive extruders to be able to print with these types of filaments while most 3D printers have Bowden extruders.

Some examples of flexible filaments include TPE or Thermoplastic Elastomer, flexible PLA, TPU or Thermoplastic Polyurethane, TPC or Thermoplastic Copolyester, and FPE or Flexible Polyester.

Dissolvable and Porous 3D Printing Filaments

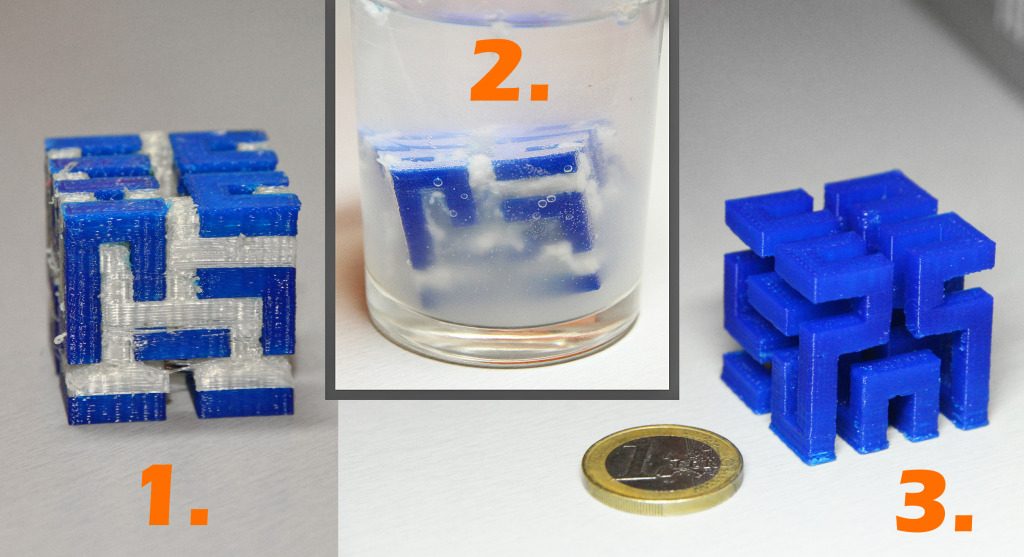

In the category of specialised 3D printing filaments, you’ll find all types of options such as dissolvable and porous filaments. Dissolvable 3D printing filaments are mainly used to create support structure of various types. While porous 3D printing filaments are used when a different types of texture is desirable.

In the category of specialised 3D printing filaments, you’ll find all types of options such as dissolvable and porous filaments. Dissolvable 3D printing filaments are mainly used to create support structure of various types. While porous 3D printing filaments are used when a different types of texture is desirable.

Examples of dissolvable filaments are PVA or Polyvinyl Acetate and HIPS or High Impact Polystyrene. PVA is most suitable as a support structure when you’re trying to print complex objects with PLA while HIPS is most suitable for same applications but with ABS. Within the porous filaments category, however, your options will include jelly filaments, foamy filaments, and felty filaments.

Leave a Reply