The potential of 3D printing as a new technology is incalculable. It’s a technology that is expected to change the world as we know it. This is common knowledge despite the fact that 3D printing technology is still in its nascent stages. In fact, 3D printing technology is expected to develop in the future to such an extent that experts are projecting exponential growth in the already numerous advantages of 3D printing.

The Advantages of 3D Printing

It is important to note that the advantages of 3D printing are most relevant to the manufacturing sector as opposed to the direct consumer sector. In other words, manufacturing grade, large scale 3D printers will bring far more change in human society than personal 3D printers ever will be able to.

It is important to note that the advantages of 3D printing are most relevant to the manufacturing sector as opposed to the direct consumer sector. In other words, manufacturing grade, large scale 3D printers will bring far more change in human society than personal 3D printers ever will be able to.

What this means is that the majority of 3D printing technology or industry analyses you’ll come across will be based around the manufacturing aspect as opposed to the personal use aspect. The same holds true for the vast majority of advantages of 3D printing.

Most advantages of 3D printing listed here will, thus, revolve around the manufacturing applications of the technology. At the same time, you need to realise that even though our focus will be on manufacturing, some advantages of 3D printing may actually be relevant to personal use as well.

The vast majority of advantages of 3D printing are similar to the advantages of automation. In fact, you can see 3D printing technology as an advanced type of automation. This abstract idea will become clearer once you go through the following list of advantages of 3D printing.

Applications of 3D Printing Are Limitless

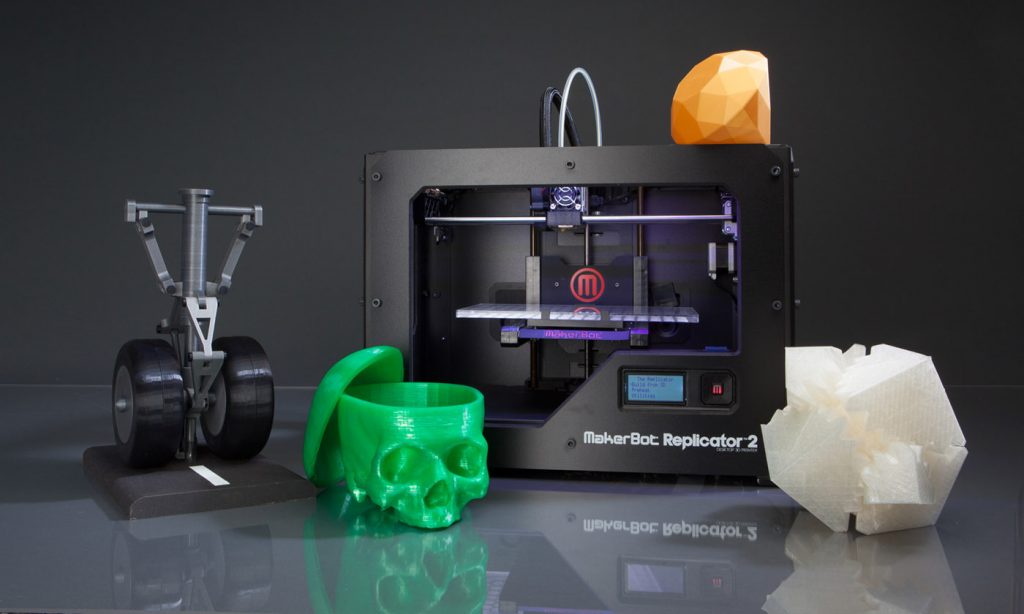

Let get the most obvious of the numerous advantages of 3D printing out of the way. 3D printing applications are limitless. Even though the 3D printing technology has been around for quite some time now (think decades), we’ve still only scratched the surface as to how many different ways we can use it.

Let get the most obvious of the numerous advantages of 3D printing out of the way. 3D printing applications are limitless. Even though the 3D printing technology has been around for quite some time now (think decades), we’ve still only scratched the surface as to how many different ways we can use it.

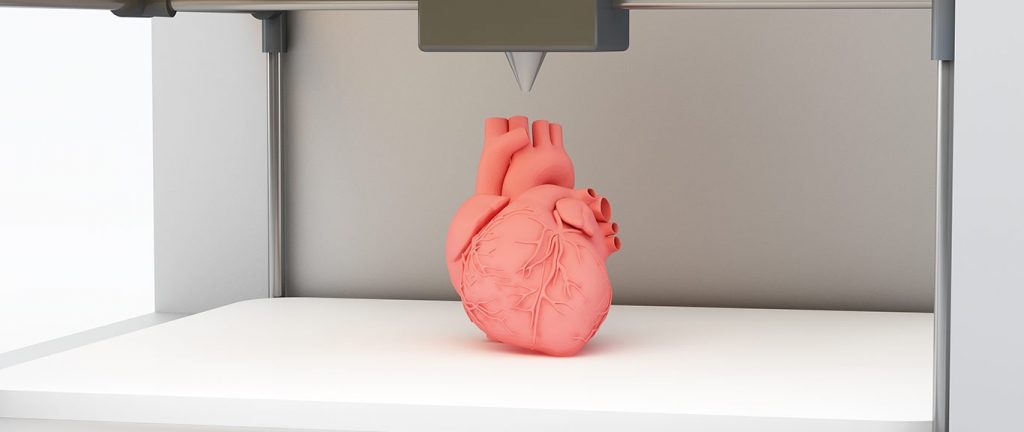

In fact, the more the 3D printing technology evolves the more applications we’re going to develop for it. Even now, 3D printing applications that the world is aware of are astounding. Consider the fact that we can now use 3D printing for creating body parts, food, basic household knickknacks, and even whole houses.

The perfect proof that the applications of 3D printing technology are only going to grow and become more diverse is that NASA is planning to use it in space exploration. There are suggestions for creating whole new space habitats with 3D printing technology.

3D Printing Complex Objects Is Cheaper and Faster

Another of the many advantages of 3D printing is that it is cheaper and faster to create more complex objects than it is to create simple objects with 3D printing. The reason for this is hidden in the actual 3D printing process. If you read our 3D printing guide, then you already know that in 3D printing a print head lays down the material in layers.

Another of the many advantages of 3D printing is that it is cheaper and faster to create more complex objects than it is to create simple objects with 3D printing. The reason for this is hidden in the actual 3D printing process. If you read our 3D printing guide, then you already know that in 3D printing a print head lays down the material in layers.

When multiple layers are deposited one on top of the other, the actual object begins to take shape. Complexity of objects is typically determined by how solid they are. The less solid the object being 3D printed is, the more complex it will be considered.

Critically, complex objects require less material to be laid down by the 3D print head. This directly means that the 3D printer will take less time to print the object. It also means that lesser material will be used to 3D print complex objects when compared to simpler or more solid objects.

Since the operating cost of a 3D printer comprises entirely of the cost of the filament or material, 3D printing complex objects also turns out to be cheaper than 3D printing solid objects.

3D Printing Makes Customised Manufacturing Easier

One of the biggest advantages of 3D printing is that it makes it easier for manufacturers to create more customised products. This is possible because, typically, 3D printers print objects one at a time. While a series of 3D printers can be tasked to create the same product or a sequence of products can be queued on the same 3D printer, the actual printing will still be individual.

One of the biggest advantages of 3D printing is that it makes it easier for manufacturers to create more customised products. This is possible because, typically, 3D printers print objects one at a time. While a series of 3D printers can be tasked to create the same product or a sequence of products can be queued on the same 3D printer, the actual printing will still be individual.

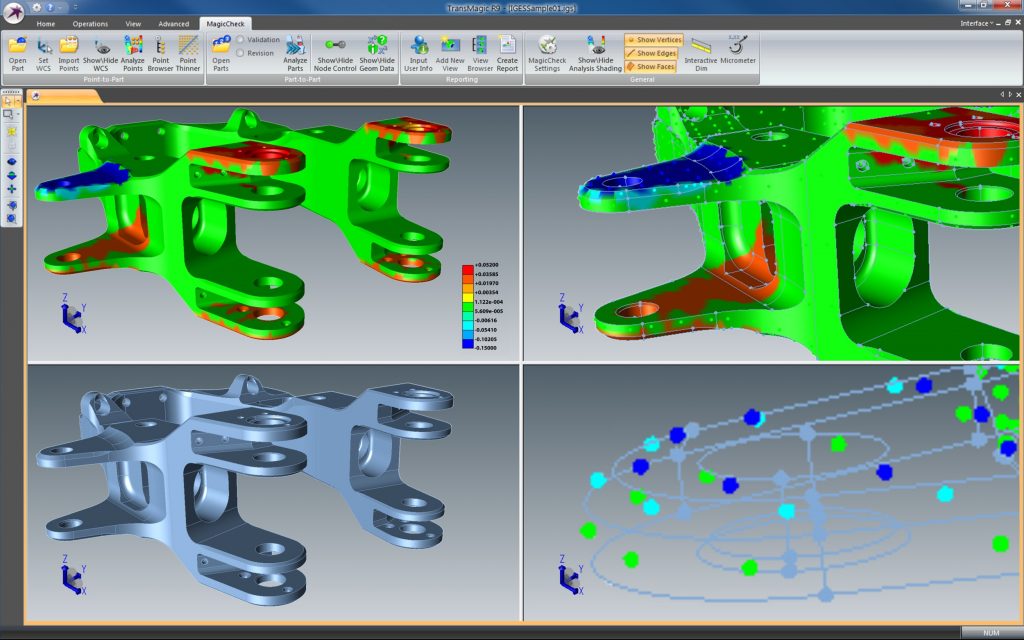

The actual 3D printing process involves designing the 3D model of the product and then sending it to the 3D printer to print. Such a process makes it very easy for the manufacturer to make minor changes to the 3D models being printed.

For instance, consider a product that is available in a specific configuration of 10 features. If a user wanted the same product with the nine of the same features but a separate feature different from the tenth feature, then it would be very easy for the manufacturer to oblige. All he’ll need to do is make minor changes to the 3D model before sending it over to the machine.

Similarly, there could be any number of configurations that the manufacturer will be able to create for any number of his clients with his 3D printer. In a world of consumer disaggregation, this is easily one of the most potent advantages of 3D printing.

Assembling Components Is Unnecessary With 3D Printing

Conventional production processes entail manufacturing individual components and then assembling them into a working product. As a result, the assembly phase has to be accounted for in virtually all conventional production processes. The same is not true in the case of additive manufacturing which is clearly one of the more cost effective advantages of 3D printing.

Conventional production processes entail manufacturing individual components and then assembling them into a working product. As a result, the assembly phase has to be accounted for in virtually all conventional production processes. The same is not true in the case of additive manufacturing which is clearly one of the more cost effective advantages of 3D printing.

In 3D printing, the assembly phase is completely redundant because the 3D printer can print a product in its entirety including any and all moveable components. While 3D printing products with moveable parts may be slightly more complicated than products that don’t have moveable parts, the removal of the assembly stage from the production process can turn out to be very cost effective and time efficient.

Barring Designing, 3D Printing Requires No Specialised Skills

One of the problems that many manufacturing industries face is that of insufficient skilled labour. Whenever some special skills are required for a particular task within the production process, the workforce performing the task is known as skilled labour.

One of the problems that many manufacturing industries face is that of insufficient skilled labour. Whenever some special skills are required for a particular task within the production process, the workforce performing the task is known as skilled labour.

Depending on the industry in question, skilled labour can be created through formal education such as engineering or on the job training as seen in the case of specialised manufacturing machines. Most manufacturing industries require skilled labour at multiple stages of the whole production process.

In 3D printing, however, skilled labour is required only for the designing stage of the process. Still, the type of skilled labour required isn’t too expansive. During the phase in which 3D models are designed, skilled labour means having the knowledge to manage one or more Computer Aided Designing (CAD) software programme.

Once the design has been created, no skilled manpower is needed to monitor or operate the 3D printing machine as that stage of the production process is completely autonomous.

There is no Lead Time between Design and the Actual Prototype

With most traditional production processes, lead times are involved between multiple stages. If a product has been designed, then it takes time for the prototype creation process to begin. Once a product prototype is created, it takes time for the prototype testing process to begin. After the prototype testing is complete, it takes time for the actual production process to begin.

Moreover, if there are revisions or modification to the product, then the lead time increases exponentially also. Lead times are virtually non-existent in additive manufacturing which is one of those critical advantages 3D printing that must not be ignored because they save time, effort, and money.

So, those were the major advantages of 3D printing from the perspective of manufacturing related applications. However, most of these advantages of 3D printing apply to personal use of the technology as well such as limitless applications, low costs and high speeds, ease of customisation, and elimination of the assembly stage.

While the advantages of 3D printing are many, it doesn’t mean that 3D printing is completely free of flaws. There will be disadvantages of 3D printing that the world will have to cope with before the technology truly takes off. In the next post, we’ll take a look at those disadvantages of 3D printing.

Leave a Reply